What is pasteurization?

Pasteurization is the process of heating foods and beverages to kill pathogens and make them safe for human consumption, and to ensure they remain safe for months or even years.

Pasteurization differs from full sterilization in that does not completely eliminate all biological agents. Rather, it is designed to use just enough heat to prevent spoilage, while minimizing the impact on the flavour and aromatic qualities of the product.

That means pasteurization is a balancing act of risk management and trade-offs. Too much heat can affect taste, aroma, and mouthfeel. Too little and you may end up dealing with wasted product, spoilage, and a costly recall. By accurately measuring pasteurization units (`PU`), you can make an informed decision about how much heat to use, and how much time is right for your product.

Many foods and beverages are treated with pasteurization, but in this article we’ll focus on beer, cider, and wine.

How is it measured?

Pasteurization is measured in pasteurization units (`PU`) which are defined as the sterilising effect observed for one minute at a temperature known as the reference temperature (`T_(ref)`). The sterilising effect increases exponentially with temperature at a rate defined by the coefficient of thermal resistance (`Z`).

`PU` are calculated by the following equation:

`PU = t*10^(((T-T_(ref))/Z))`

`PU`: Pasteurization Unit

`t` : Time (in minutes)

`T`: Temperature (In Celsius)

`T_(ref)`: Reference Temperature (In Celsius)

`Z`: Coefficient of thermal resistance (In Celsius)

Different species of organisms have different thermal resistance, and thus different values for `T_(ref)` and `Z`, so choosing values appropriate for the type of food being pasteurized (and the type of organisms that like to live in that food) is paramount. Luckily, these constants are well-established for fermented beverages.

In their paper Thermal death time studies on beer spoilage organisms, Del Vecchio et. al. observed the sterilising effect of various temperatures applied to brewing, and derived the constants `T_(ref)=60°C` and `Z=6.94` for use in brewing and fermented beverages.

That led to the common calculation, published in Andrew Lea’s Fermented Beverage Production and often cited on brewing forums:

`PU = t*1.393^(T-60)`

OK great, but how do I use that?

To calculate the number of `PU`, you can simply substitute the temperature `T` and a time `t` into the formula above. So if you pasteurize for 15 minutes at 63°C, your formula would be:

`PU = 15*1.393^(63-60) = 40.5PU`

It's important to remember that this is a mathematic model, and reality is more complicated. Technically you could run at 40°C for a million minutes until it shows `PU=6`, however, you don't really achieve lethality until reaching `T_(ref)`. Even worse, low temperatures may actually be an ideal pathogen incubation temperature. For this reason, the Craft Metrics Pasteurization Computer only counts `PU` that occur above `T_(ref)`.

And simply plugging in a temperature and time isn't realistic. It doesn’t account for the ramp up to 63°C and the ramp back down, during which `PU` are still accumulating, albeit at a slower rate. To know the true total, you would need to calculate the `PU` based on the average temperature during each minute, or each second, and add them all up.

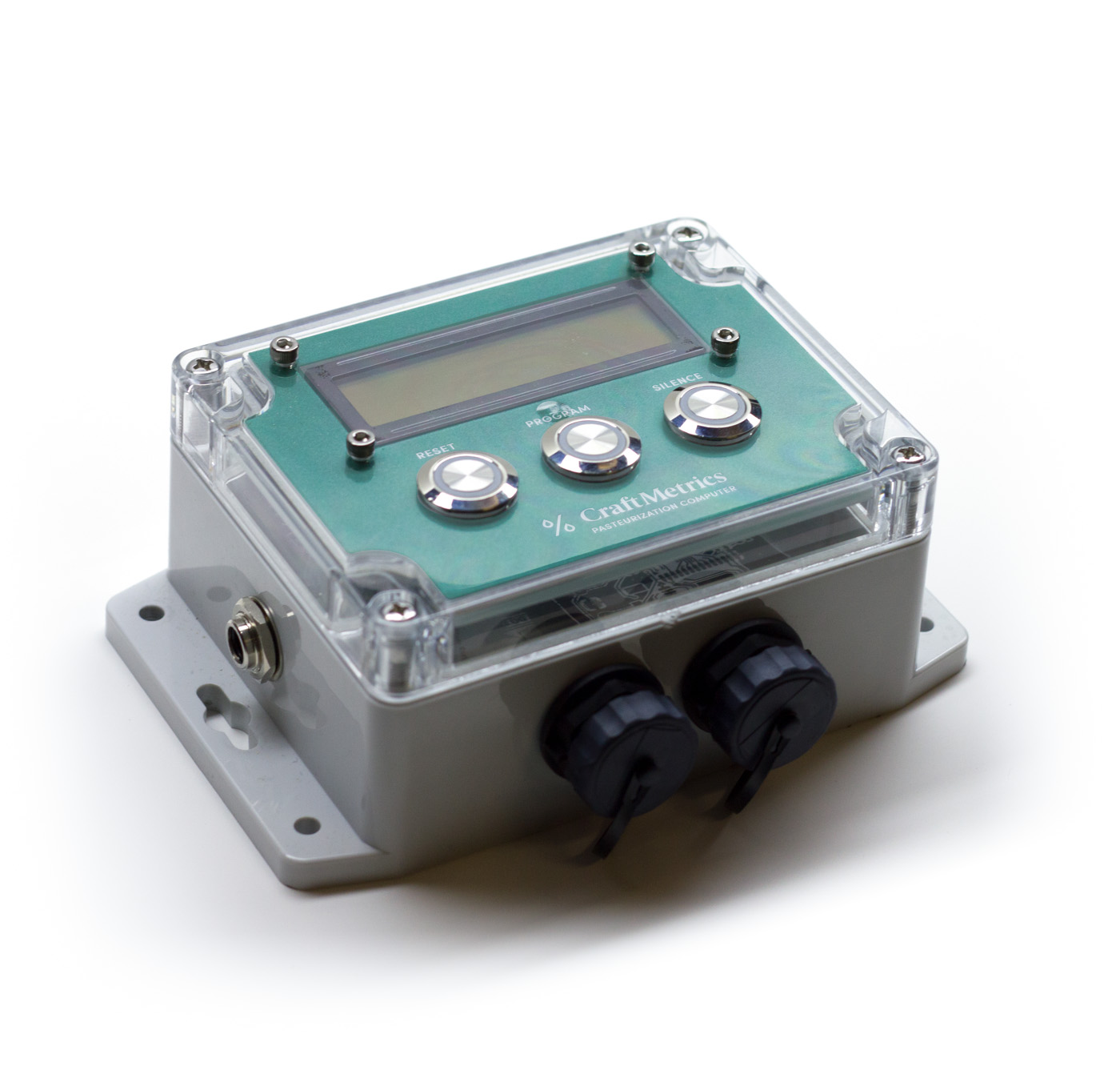

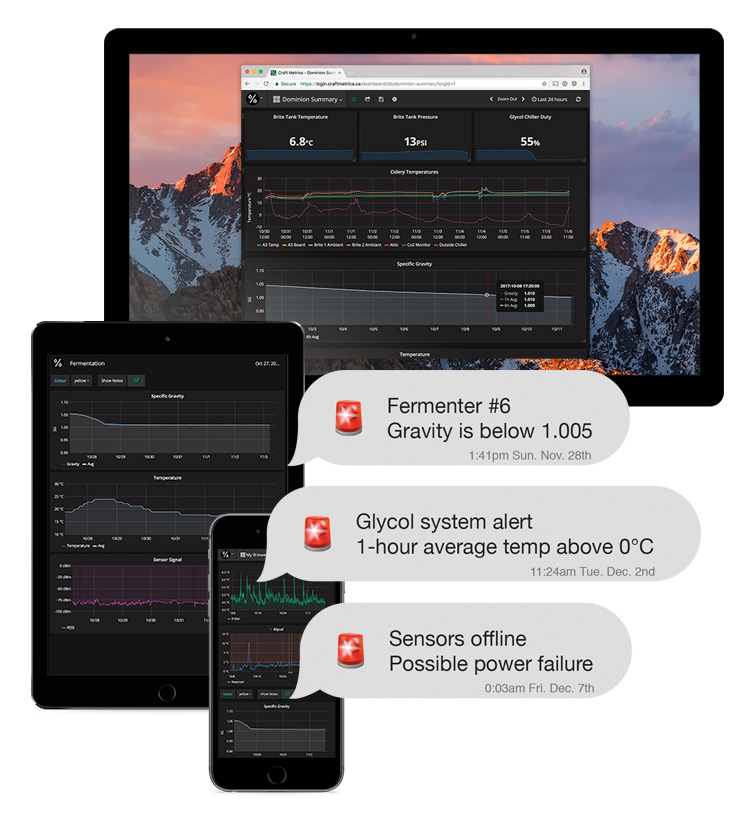

The Craft Metrics Pasteurization Computer is a measurement device that does this. It includes a temperature probe to measure the continuous temperature inside the bottle, and accumulates `PU` at 10-second intervals. Temperatures and `PU` plots are stored and can be reviewed from the Craft Metrics app.

In Part 2, we’ll share how to put this theory into practice and pasteurize craft fermented beverages on a small scale.

References

H. W. Del Vecchio, C. A. Dayharsh, and F. C. Baselt.

Thermal death time studies on beer spoilage organisms.

Proceedings of the American Society of Brewing Chemists, 1951, page 45.

Andrew G. H. Lea and John R. Piggott, editors.

Fermented Beverage Production. 2nd edition.

Springer, 2003.

Support for this project

Funding for this project has been provided by the Governments of Canada and British Columbia through the Canadian Agricultural Partnership, a federal-provincial- territorial initiative. The program is delivered by the Investment Agriculture Foundation of BC.

Opinions expressed in this document are those of the author and not necessarily those of the Governments of Canada and British Columbia or the Investment Agriculture Foundation of BC. The Governments of Canada and British Columbia, and the Investment Agriculture Foundation of BC, and their directors, agents, employees, or contractors will not be liable for any claims, damages, or losses of any kind whatsoever arising out of the use of, or reliance upon, this information.